Proterial Metals, Ltd. TOP > Products > Metals for Automobiles

> Clad metals for batteries

Metals for Automobiles

●Clad metals for batteries

【Features】

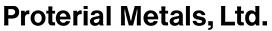

Besides high conductivity, these clad metals can be used for resistance welding and various other types of welding, and are useful for increasing the battery performance (higher volume and smaller size) and improving productivity as well.

The above figures are for reference only and are not guaranteed.

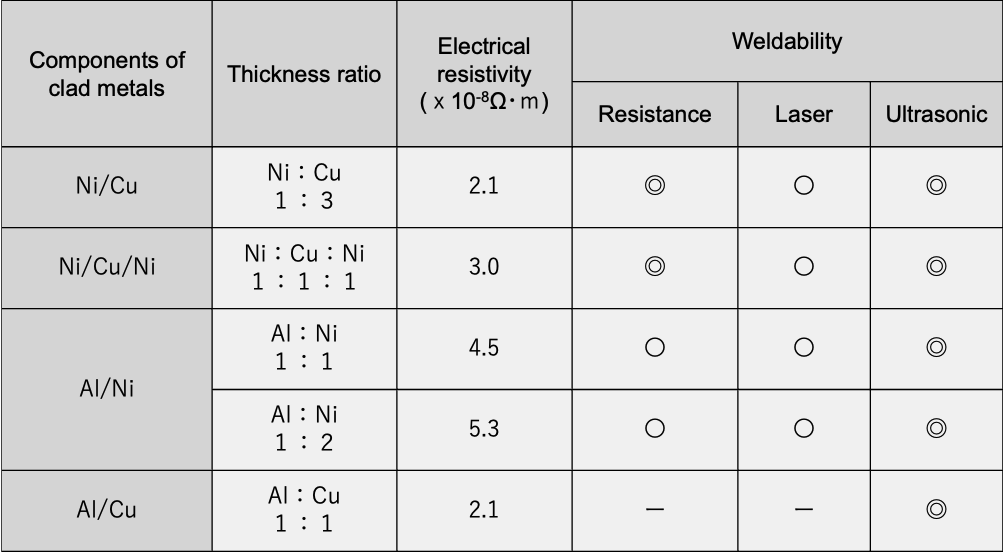

【Usage example 1】

[Internal lead for batteries]

Nickel-Clad Copper and Copper-Clad, Aluminum for batteries (Ni/Cu, Ni/Cu/Ni, Cu/Aℓ)

These materials have lower electrical resistance than pure nickel, coupled with excellent heat dispersion properties and processability. Due to these characteristics, the materials enable production of various types of larger output and higher capacity batteries.

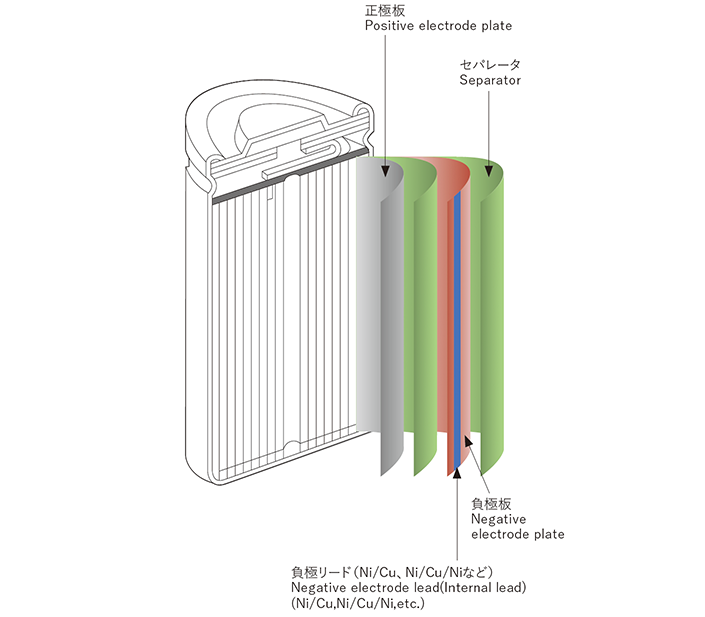

【Usage example 2】

[External terminal for batteries]

Aluminum clad nickel for batteries (Aℓ /Ni)

These materials have good conductivity and processability. They can be directly welded to lithium-ion battery aluminum casings and terminals.

- Products

-

- Metals for Environment and Energy

- Metals for Automobiles

- Metals for Communications, Semiconductors and Packages

-

- Iron-Nickel-Cobalt alloys

- Iron-Nickel alloys

- Low thermal expansion alloys for precision equipment

- Permalloys

- Clad metals for heat spreaders

- Metals for laser diodes

- Clad metals for smartphones

- Bimetals

- Metal parts for package sealing

- Au coated Ni-P particles

- Lead pins

- Metals for functional parts

- Copper alloy strip for semiconductor lead frames

- Dual gauge copper strip

- Plated copper strip and dual gauge copper strip

- Copper strip for heat sinks and heat spreaders

- Copper strip for ceramic substrates

- General industry

- Metals for Domestic Electrical Applications

- Metals for Special Applications

- Material technologies

-

- Material technologies

- Processing technology

- Surface treatment technologies

- Corporate Profile

- Contact Us

PAGE TOP