Proterial Metals, Ltd. TOP > Technologies > Processing technology

> Brazing

Processing technology

●Brazing

We can braze or solder from low to high melting points materials, such as Au-Sn alloy, silver brazing, and solder, into the required shapes. Our brazing technology of hermetic sealing materials used for ceramic packages contributes to the further downsizing of electronic components.

【Applications】

- ・SAW Filters

- ・Crystal Oscillators

- ・Sensors

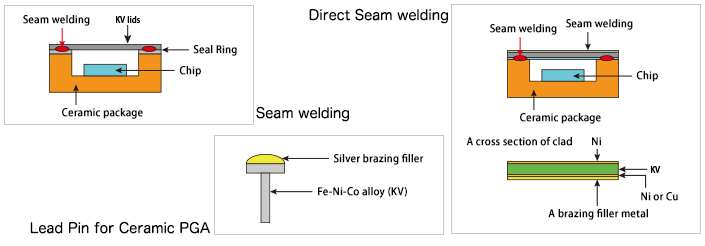

- ・Ceramic PGA

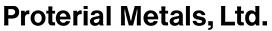

Seam welding

Ni-plated Fe-Ni-Co alloy (KV) lid is welded to the seal ring mounted on the ceramic package by electronic resistance roller (seam welding).

(There are two types of Ni plating: electrolytic plating and electroless plating.)

Direct seam welding

The lids are directly welded on the ceramic package whose top side is metalized without a seal ring. The absence of a seal ring makes it possible to realize a thinner package.

The lid for direct seam is processed of four-layer clad material composed of Ni/Kv/Cu or Ni /brazing.

In direct seam welding, brazing material is melted and used for sealing. The selection of brazing is therefore important. We provide various brazing material.

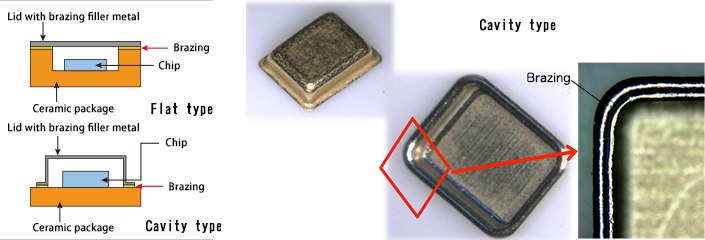

Brazing

A solder material attached to the lid is melted in a heat treatment furnace to process sealing. This is advantageous to smaller electronic components. There are two types of lids, one in which the cavity (the space of elements) is created on the package side, and the other in which the cavity is created on lids. We can offer both types.

【Materials】

- ・ASKNA-H

- ・ASKNA-P

- Products

-

- Metals for Environment and Energy

- Metals for Automobiles

- Metals for Communications, Semiconductors and Packages

-

- Iron-Nickel-Cobalt alloys

- Iron-Nickel alloys

- Low thermal expansion alloys for precision equipment

- Permalloys

- Clad metals for heat spreaders

- Metals for laser diodes

- Clad metals for smartphones

- Bimetals

- Metal parts for package sealing

- Au coated Ni-P particles

- Lead pins

- Metals for functional parts

- Copper alloy strip for semiconductor lead frames

- Dual gauge copper strip

- Plated copper strip and dual gauge copper strip

- Copper strip for heat sinks and heat spreaders

- Copper strip for ceramic substrates

- General industry

- Metals for Domestic Electrical Applications

- Metals for Special Applications

- Material technologies

-

- Material technologies

- Processing technology

- Surface treatment technologies

- Corporate Profile

- Contact Us

PAGE TOP