Proterial Metals, Ltd. TOP > Technologies > Materials Technologies

> Materials Technologies

Materials Technologies

●Alloy materials, clad metals, Copper materials

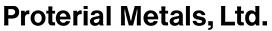

Alloy coil and sheet manufacturing process

Raw materials are melted into an alloy in combination with the required additives. Then, the alloy undergoes hot rolling, cold rolling and heat treatment, and is finished to the required properties and dimensions.

*Certain products may have some manufacturing processes outsourced.

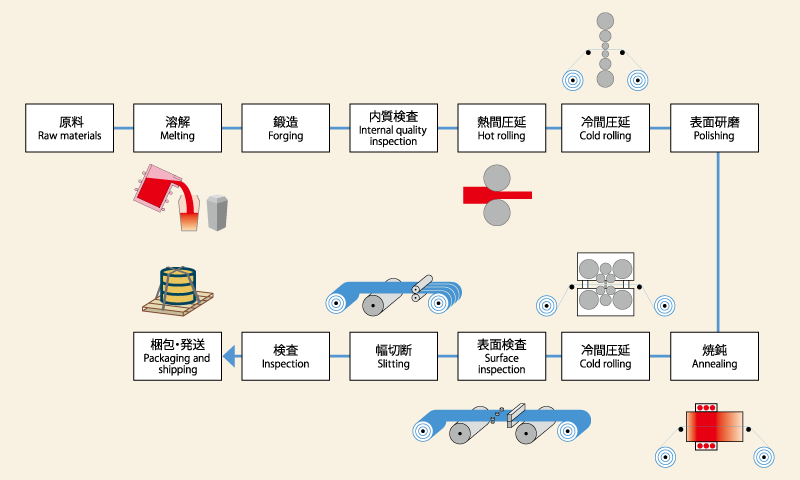

Clad metals

Clad metals manufacturing process

Production line developed to ensure high-quality clad metals

Surface-polished coils are bonded by pressure weld rolling, then annealed for increased bonding strength.

*Certain products may have some manufacturing processes outsourced.

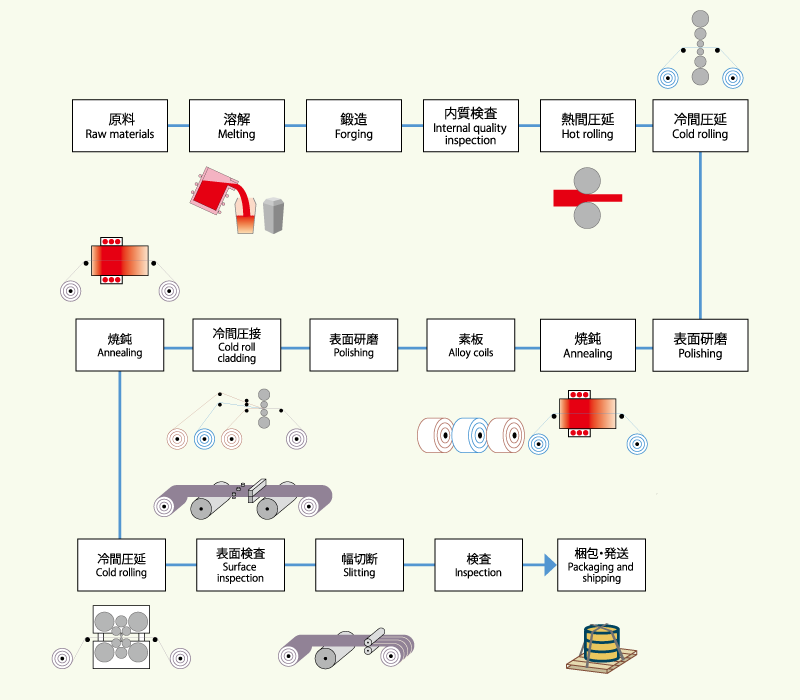

Copper materials

Process of copper strips, bars, rods, formed bars, and hollow conductors

We offer a wide range of products from formed bars with basic cross-section shapes, such as rectangles and circles, to those with complex cross-section shapes that are effective in reducing customer processing costs.

*Certain products may have some manufacturing processes outsourced.

- Products

-

- Metals for Environment and Energy

- Metals for Automobiles

- Metals for Communications, Semiconductors and Packages

-

- Iron-Nickel-Cobalt alloys

- Iron-Nickel alloys

- Low thermal expansion alloys for precision equipment

- Permalloys

- Clad metals for heat spreaders

- Metals for laser diodes

- Clad metals for smartphones

- Bimetals

- Metal parts for package sealing

- Au coated Ni-P particles

- Lead pins

- Metals for functional parts

- Copper alloy strip for semiconductor lead frames

- Dual gauge copper strip

- Plated copper strip and dual gauge copper strip

- Copper strip for heat sinks and heat spreaders

- Copper strip for ceramic substrates

- General industry

- Metals for Domestic Electrical Applications

- Metals for Special Applications

- Material technologies

-

- Material technologies

- Processing technology

- Surface treatment technologies

- Corporate Profile

- Contact Us

PAGE TOP